What is SMT Assembly reflow soldering?

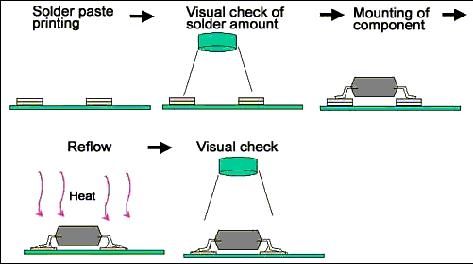

SMT Assembly reflow soldering is to remelt the paste-like solder pre-allocated on the printed board pad to realize the soft mechanical and electrical connection between the solder end or the pin of the surface mount component and the printed board pad. Brazing. The technology of SMT Assembly reflow soldering is not unfamiliar to us in the field of electronic manufacturing industry. The components on the various boards of our electronic products must be soldered to the circuit board through the SMT Assembly reflow soldering. The advantage of this reflow soldering is that the temperature is easier to control, oxidation can be avoided during welding, and the cost of manufacturing products is easier to control. There is a set of electric heating circuit inside the device, which heats the nitrogen gas to a high enough temperature and blows it to the circuit board where the component is already attached, so that the solder on both sides of the component is melted and bonded to the motherboard.

Optimization method to ensure good quality of SMT Assembly reflow soldering

1. To set up a scientific SMT Assembly reflow soldering temperature curve and do real-time testing of the temperature curve regularly.

2. The soldering should be carried out according to the soldering direction during PCB design.

3. Avoid vibration of the conveyor belt during soldering.

4. The soldering effect of the first article must be checked.

5. Whether the soldering is sufficient, whether the surface of the solder joint is smooth, whether the solder joint shape is half-moon shape, the condition of tin ball and residue, the condition of continuous soldering and virtual soldering. Also check the PCB surface color changes and other conditions. And adjust the temperature curve according to the inspection results. Check the soldering quality regularly during the entire batch production process.

6. Regular maintenance of SMT Assembly reflow soldering. Due to the long-term operation of the machine, organic or inorganic contaminants such as solidified rosin are attached. In order to prevent secondary pollution of PCB and ensure the smooth implementation of the process, regular maintenance and cleaning are required.

Equipment maintenance operation precautions

1. A maintenance system for SMT Assembly reflow soldering equipment need to be formulated. We must do equipment maintenance after using SMT Assembly reflow soldering, otherwise which is difficult to maintain the service life of the equipment.

2. Daily inspection and maintenance of all parts should be carried out, and special attention should be paid to the conveyor belt to prevent it from jamming or falling off;

3. When overhauling the machine, shut down and cut off the power supply to prevent electric shock or short circuit;

4. The machine must be stable and not tilted or unstable;

5. Regularly clean the furnace, mesh belt and condenser for SMT Assembly reflow soldering, and formulate weekly, monthly and quarterly maintenance plans to ensure the quality of SMT Assembly reflow soldering.

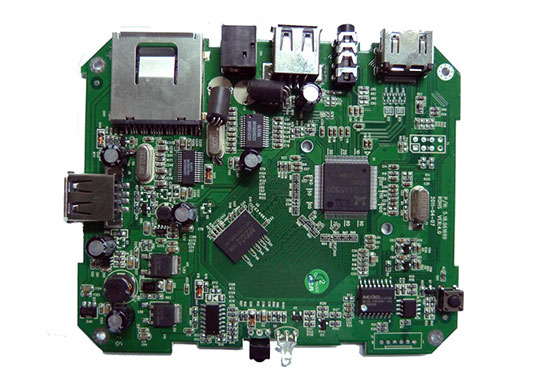

SMT Assembly Capability

1. The largest board: 310mm*410mm (SMT);

2. Maximum board thickness: 3mm;

3. Minimum board thickness: 0.5mm;

4. The smallest Chip parts: 0201 package or parts above 0.6mm*0.3mm;

5. The maximum weight of the mounted parts: 150 grams;

6. Maximum part height: 25mm;

7. The largest part size: 150mm*150mm;

8. Minimum lead part spacing: 0.3mm;

9. The smallest spherical part (BGA) spacing: 0.3mm;

10. The smallest spherical part (BGA) diameter: 0.3mm;

11. Maximum component placement accuracy (100QFP): 25um@IPC;

12. Mounting capacity: 3 to 4 million points/day.

Why Choosing Grande To Do Small Batch SMT Assembly?

1. Strength Guarantee

▪ SMT factory: With imported SMT machines and multiple optical inspection equipment, which is able to produce 4 million points per day. Each process is equipped with QC personnel who will keep an eye on product quality.

▪ DIP production line: Two wave soldering machines and more than 10 employees who have worked for over three years. That’ s to say, these workers are highly skilled and can weld various SMT & DIP components.

2. Quality Assurance With High Cost Performance

▪ High-end equipment can paste precision special-shaped parts, BGA, QFN, 0201 package. It can also be soldered prototype pcba via SMT machine and placing bulk materials by hand.

▪ Both samples, small and large batches can be produced. And there is no SMT Machine starting cost.

3. Rich Electronic Products SMT Soldering Experience With Stable Delivery

▪ Accumulated services to thousands of electronics companies, involving SMT soldering services for various types of automotive equipment and industrial control motherboards. Furthermore, PCBA products are often exported to Europe and the United States, and the quality is able to be affirmed by new and regular customers.

4. Strong Maintenance Ability & Reliable After-Sales Service

▪ The maintenance engineers have sophisticated experience so that those defective boards caused by all kinds of smt soldering can be repaired. Meanwhile, ensuring the connectivity rate of each circuit board also make sense.

▪Order problems feedback will get response, solution and solved as soon as possible.