Nowadays, the resin plugging technology is mainly used in the following products:POFV technology resin plugging;Inner layer HDI resin plug hole; Through hole resin plugging.

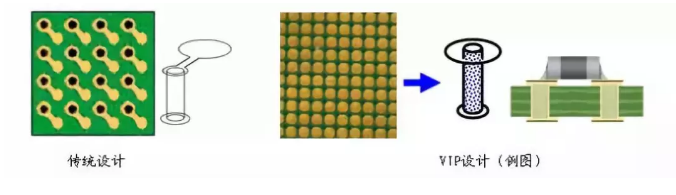

POFV technology

What are the technical principles?

A. Plug the via hole with resin and then plate copper on the surface of the hole.

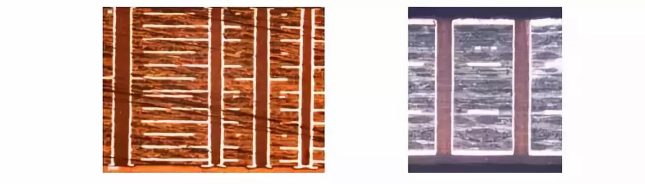

As shown below:

B. Slice example:

What are the advantages of POFV technology?

Reducing the hole spacing and the area of the board,

Solving the problem of lines and layout and increasing the density of layout.

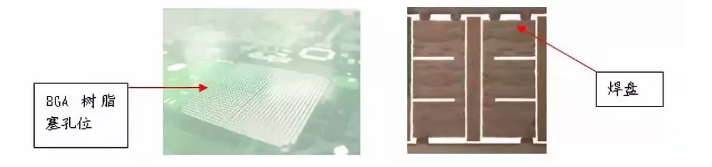

Inner layer HDI resin plugging

What are the technical principles?

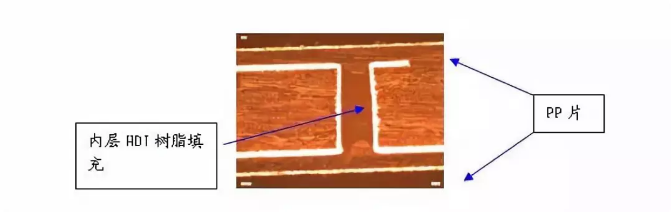

The buried holes of the inner layer HDI were plugged with a resin and then pressed. This process balances the contradiction between the control of the thickness of the pressed dielectric layer and the design of the inner layer HDI buried hole.

Two contraditions

If the inner layer HDI buried hole is not filled with resin, the board will explode when it is overheated and directly scrapped;

If the resin plug hole is not used, multiple PPs are needed for pressing to meet the requirements of the glue filling. As a result, the dielectric layer's thickness of the layers may be thicker due to increase the PP sheet.

Case diagram

What is the application of inner layer HDI resin plugging?

1. The inner layer of HDI resin plugging is widely used in HDI products to meet the design requirements of thin dielectric layer requirements of HDI products;

2. For the buried hole product with buried hole design for the inner layer HDI, because the intermediate combined medium design is thin, it is often necessary to increase the flow of the inner layer HDI resin plug hole.

3. Some of the blind hole products, due to the thickness of the blind hole layer is more than 0.5mm, the pressure filling can not fill the blind hole fully, so it need to use the resin plugging to fill the blind hole and avoid the copper free problem of the hole in the following process.

What is the through hole resin plugging?

some 3G products, consider to the thickness of the board reaches 3.2mm or more, in order to improve the reliability of the product, or the reliability of the green oil plugging, the resin plugging will be used during the available budget. This is a major product category that resin plugging technology has been promoted recently.