What is PCBA Burn-In Test?

In order to ensure the stability and reliability of PCBA products, after the PCBA processing is completed, it is best to conduct a casual inspection of Burn-In Test.

What is the main purpose?

Burn-In Test is to simulate by combining the high temperature, low temperature, high and low temperature changes and electric power. The daily use environment of the product exposes defects of PCBA, such as poor soldering, component parameter mismatch, and faults caused during debugging, so as to eliminate and improve, and the non-defective PCBA board will play a stable parameter role.

How many standards it has?

For PCBA Burn-In Test. You will be easy to find the general problems by according to these three ones.

1. Low temperature operation: After the PCBA board is placed at a temperature of -10±3°C for 1h, under this condition, all the procedures should be run with the rated load, 187V and 253V, and the procedure should be correct.

2. High-temperature work: After placing the PCBA board at 80±3°C/h, under this condition, with load, 187V and 253V, all programs should be powered on, and the program should be correct.

3, high temperature and high humidity work: the PCBA board under the conditions of temperature 65 ± 3 ° C, humidity 90-95%, time 48h, with rated load power running each program, each procedure should be correct.

What are the specific practices?

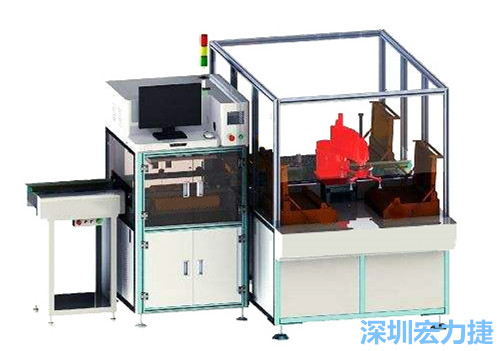

1. Place the PCBA board at ambient temperature into the heat aging equipment at the same temperature, and the PCBA board is in operation.

2. Reduce the temperature inside the equipment to the specified temperature at a specified rate. After the temperature in the equipment has stabilized, the PCBA board should be exposed to low temperature for 2 h.

3. Raise the temperature inside the equipment to the specified temperature at a specified rate. After the temperature in the equipment has stabilized, the PCBA board should be exposed to high temperature for 2 h.

4. Reduce the temperature inside the equipment to room temperature at a specified rate, repeat until the specified aging time, and measure and record the PCBA board according to the specified aging time.

After the above process Burn-In Test, the PCBA board can be safely delivered to the customer. The advantage of this is that the customer is assured that the repair rate is extremely low and the quality is more stable.